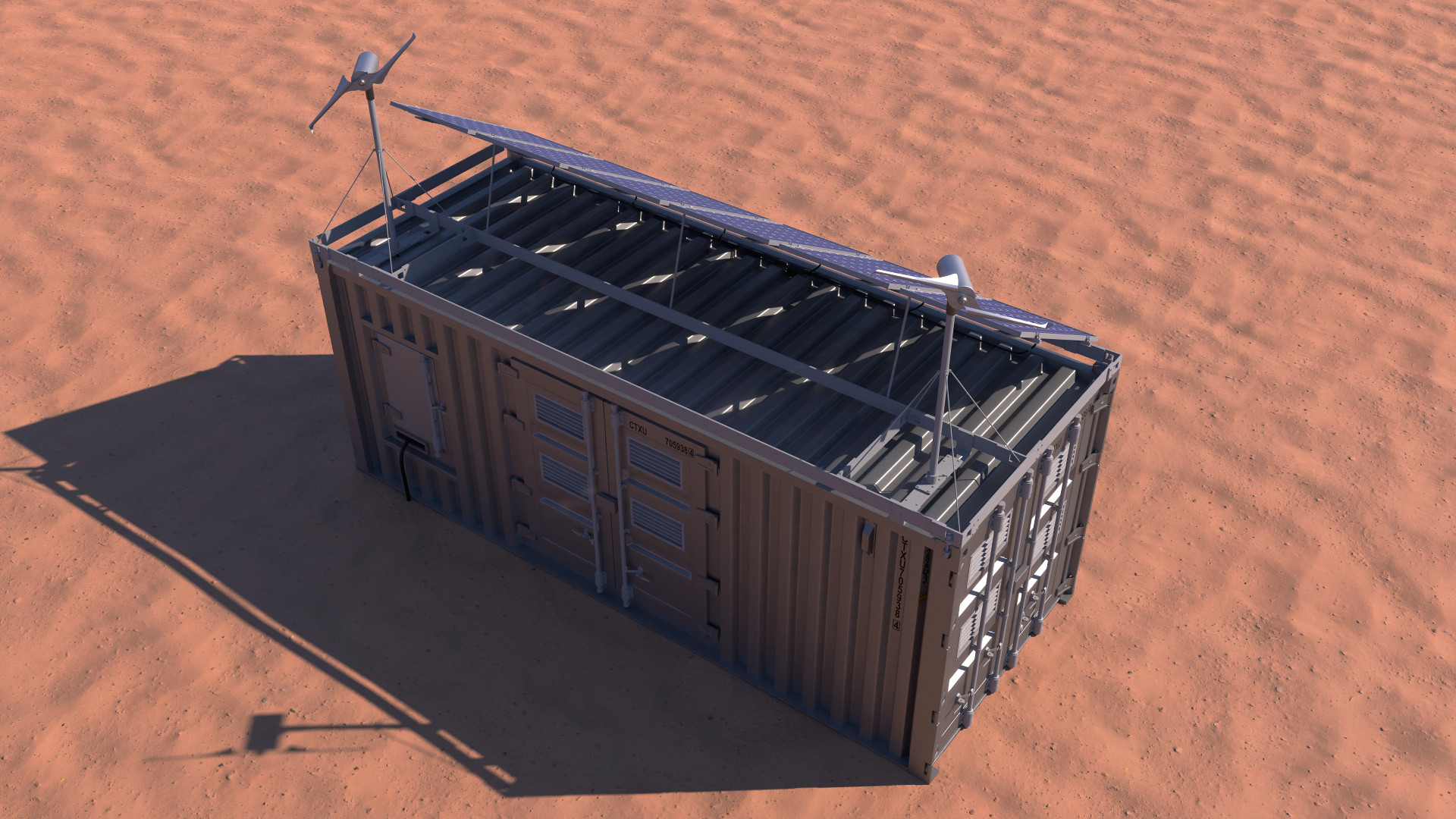

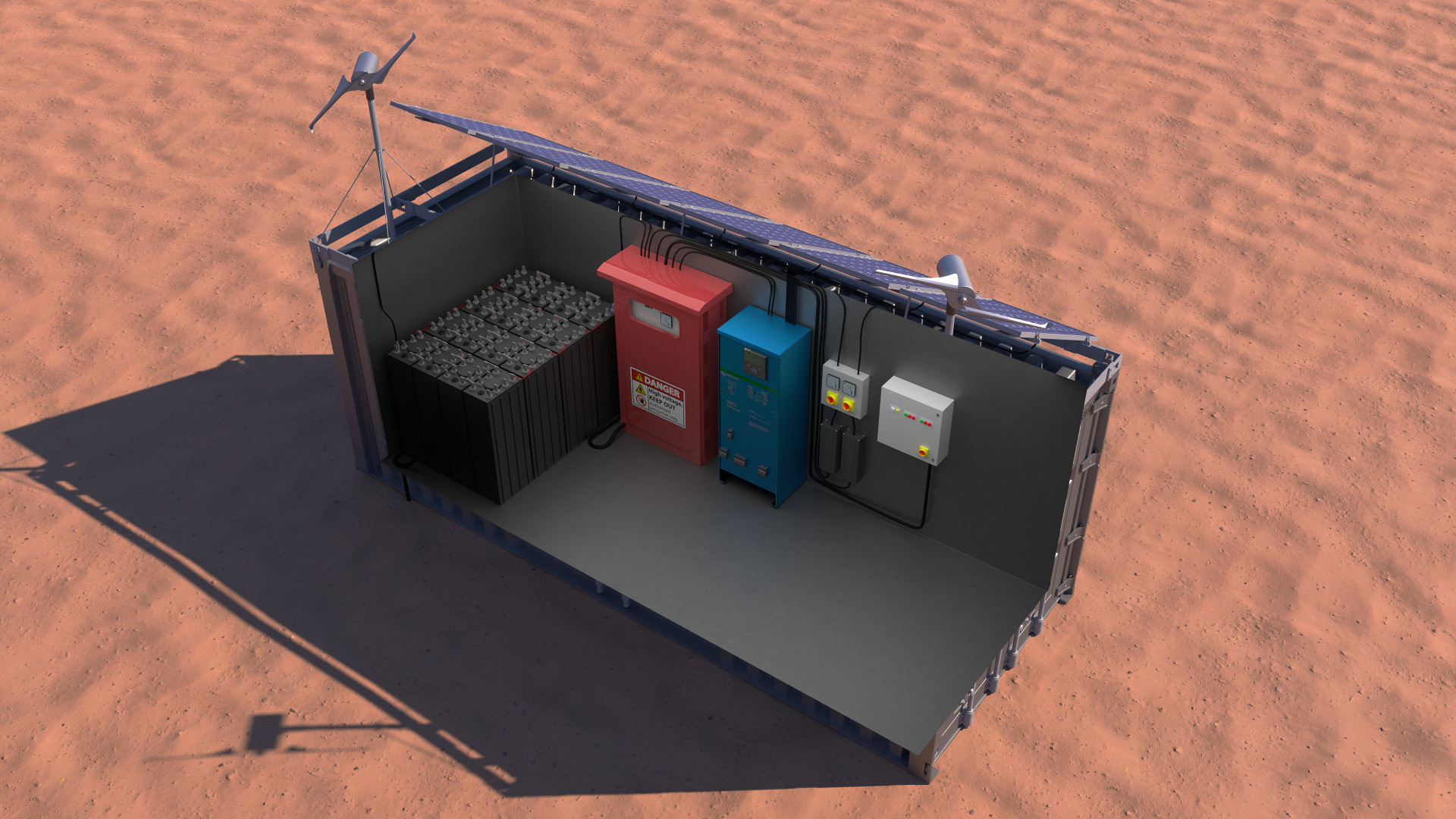

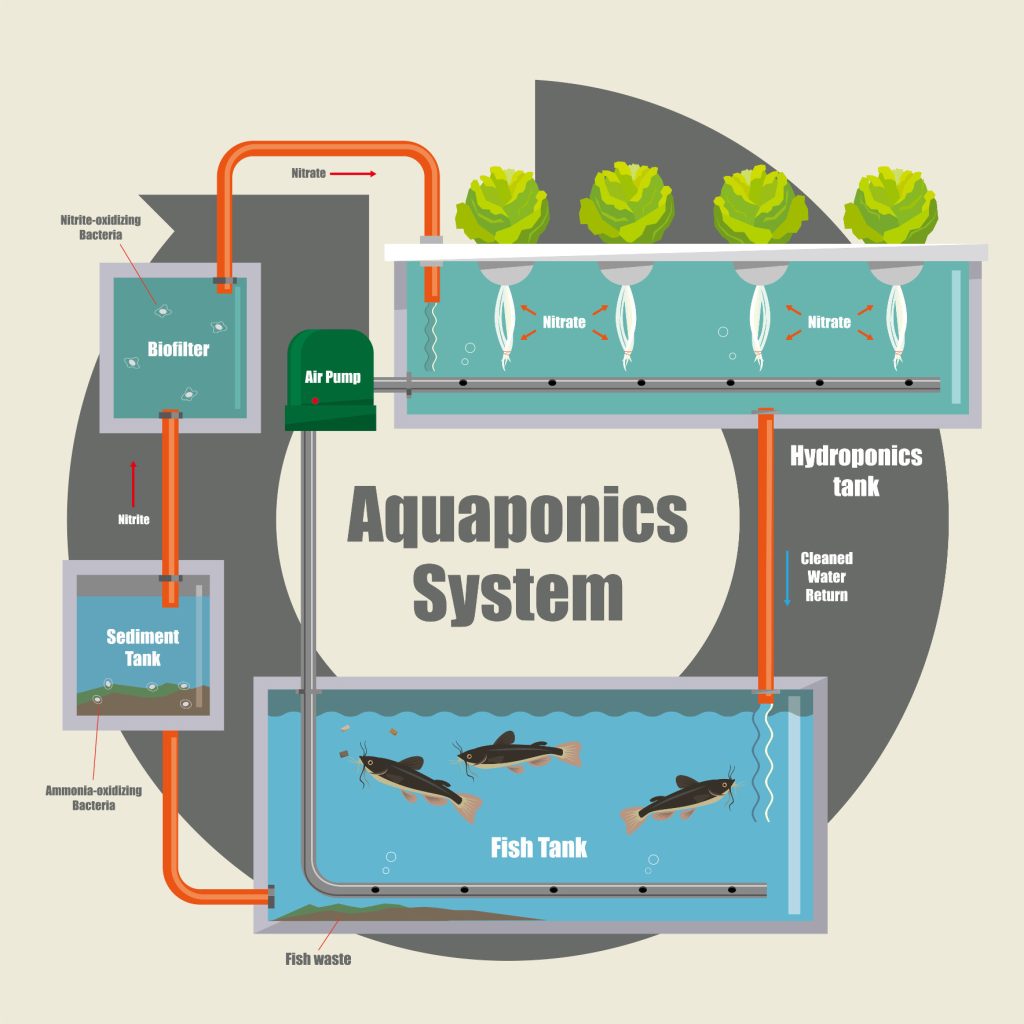

The energy demand of the module houses and external plants (e.g. aquaponics) is continuously secured autonomously by combined technologies. Preferably, the energy management is realized in a dedicated energy container.

- HCPV Photovoltaics

- Wind energy

- Heat pumps

- Solar energy

Some systems in concentrator photovoltaics are operated with active cooling, so that thermal energy can be used in addition to electrical energy (CPV-T systems). Overall efficiencies of more than 75% have already been realized in CPV-T systems. CPV systems are best suited to sunny and dry locations.

There, drinking water is often obtained by desalination plants (see under Water management). Therefore, a combination of the CPV-T and desalination systems is ideal.

Modular solutions are offered for the storage of excess energy via batteries or other innovative options (fuel cells).